Solar inverter system

Dealing with errors in solar inverters can be frustrating, but understanding the common issues and how to fix them will help keep your system running smoothly and efficiently.

The Deye SUN-3.6/5/6K-SG03LP1-EU inverter may face various errors that can affect its performance. Understanding these errors and their solutions can help prevent downtime and maintain optimal functionality.

In this article, we’ll look at the most frequent error codes, their causes, and how to troubleshoot them effectively.

What Are the Most Frequent Issues with the Deye Inverter?

The Deye SUN-3.6/5/6K-SG03LP1-EU inverter may experience several common issues, such as communication errors1, overvoltage2, and ground faults3. Each of these can disrupt the inverter's operation, but they are usually preventable with regular maintenance and attention to system setup.

Communication failures, overvoltage, and ground faults are common errors. Identifying and troubleshooting them promptly helps keep your system functioning properly.

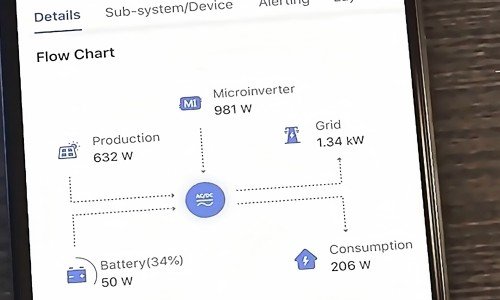

Energy flow chart

Communication Failures

Communication failures occur when the inverter cannot properly sync with the monitoring system, often due to faulty wiring or network issues. Sometimes, power surges or physical damage to the inverter’s communication ports may also cause this issue.

Overvoltage and Undervoltage

Overvoltage errors happen when the voltage supplied to the inverter exceeds its rated capacity, while undervoltage occurs when the voltage is too low for the inverter to function properly. These problems can often be avoided by ensuring proper grid voltage and system configuration.

Ground Faults

Ground faults occur when there is an unintended electrical connection between the system and the ground, often due to wiring issues or moisture. Regular inspection of connections and ensuring the inverter is installed in a dry environment can prevent these faults.

How Can You Troubleshoot Common Error Codes on the SUN-3.6/5/6K-SG03LP1-EU?

Error codes are helpful tools for diagnosing problems with your inverter. Understanding these error codes will enable you to take the right steps to resolve them. Below is a list of the most common error codes you may encounter with your Deye inverter.

The error codes help identify specific issues with the inverter. Below are descriptions of the error codes and how to resolve them.

| Error Code | Description | Solutions |

|---|---|---|

| F08 | GFDI Relay Failure | 1. When the inverter is in split-phase (120/240Vac) or three-phase (120/208Vac), the backupload N-line needs to be connected to ground. 2. If the fault persists, contact support. |

| F13 | Working Mode Change | 1. This error occurs when grid type and frequency change or when battery mode switches to "No battery". 2. It typically clears automatically. 3. If not, turn off DC and AC switches, wait a minute, and restart. 4. If the issue persists, contact support. |

| F18 | AC Overcurrent Fault | 1. Check if backupload and common load power are within the allowed range. 2. Restart the inverter and check again. 3. If the error continues, contact support. |

| F20 | DC Overcurrent Fault | 1. Check the connections of the PV modules and the battery. 2. Reduce the load power if in off-grid mode. 3. Restart by turning off DC/AC switches and turning them back on after a minute. 4. If unresolved, contact support. |

| F22 | Emergency Stop Fault | Contact your installer for further assistance. |

| F23 | AC Leakage Current Fault | 1. Check the PV side cable ground connection. 2. Restart the system 2-3 times. 3. If the issue persists, contact support. |

| F24 | DC Insulation Impedance Failure | 1. Ensure PV panel connections are secure and correct. 2. Check the inverter’s PE cable to ensure it's connected to the ground. 3. Contact support if the issue persists. |

| F26 | DC Busbar Unbalanced | 1. Wait for a while to see if the issue resolves. 2. If using split-phase mode, and L1 and L2 loads are significantly different, F26 may appear. 3. Restart the system 2-3 times. 4. If unresolved, contact support. |

| F29 | Parallel CANBus Fault | 1. Check the parallel communication cable connection and hybrid inverter communication address settings. 2. During system startup, the error will disappear once all inverters are ON. 3. Contact support if the issue persists. |

| F34 | AC Overcurrent Fault | 1. Check the backupload connection and ensure it is within the allowed power range. 2. Contact support if the issue continues. |

| F35 | No AC Grid (No Utility) | 1. Confirm whether the grid is lost. 2. Check if the grid connection is intact. 3. Ensure the switch between the inverter and grid is ON. 4. Contact support if unresolved. |

| F41 | Parallel System Stop | 1. Check if one inverter is OFF in the parallel system. 2. If unresolved, contact support. |

| F42 | AC Line Low Voltage | 1. Ensure the AC voltage is within the standard range. 2. Check the grid AC cables for proper connection. 3. Contact support if the issue persists. |

| F47 | AC Overfrequency | 1. Verify that the frequency is within the specification range. 2. Check AC cables for secure connection. 3. Contact support if unresolved. |

| F48 | AC Lower Frequency | 1. Verify that the frequency is within the specification range. 2. Check AC cables for proper connection. 3. Contact support if unresolved. |

| F56 | DC Busbar Voltage Too Low | 1. Check if the battery voltage is too low. 2. Use PV or grid to charge the battery. 3. Contact support if unresolved. |

| F58 | BMS Communication Fault | 1. This indicates a loss of communication between the inverter and battery BMS. 2. Disable "BMS_Err-Stop" in settings if you want to avoid this error. 3. Contact support if the issue persists. |

| F63 | ARC Fault | 1. This fault is specific to the US market. 2. Check the PV module cable connections. 3. Contact support if unresolved. |

| F64 | Heat Sink High Temperature Failure | 1. Check if the work environment temperature is too high. 2. Turn off the inverter for 10 minutes and restart. 3. Contact support if unresolved. |

Why Do These Errors Occur and How to Prevent Them?

Understanding the root causes of inverter errors is key to preventing future problems. Most errors occur due to improper installation, incorrect system configuration, and environmental factors. Let’s explore how to prevent these issues from happening.

Errors in the Deye inverter are often caused by installation mistakes, environmental factors, or component wear and tear. Preventative measures can significantly reduce these errors.

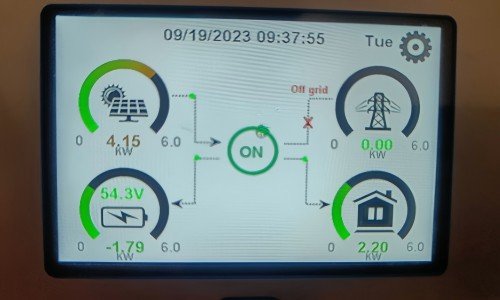

Energy monitoring screen

Installation and Configuration Issues

Many errors arise from incorrect installation or system configuration. Always ensure that the inverter is installed correctly according to the manufacturer's guidelines and that all settings are properly configured.

Environmental Factors

Extreme environmental conditions such as high temperatures, moisture, or dust can cause the inverter to malfunction. To prevent these issues, install the inverter in a well-ventilated, dry area that is shielded from direct sunlight and excessive heat. Learn more about how temperature4 and moisture can affect inverter performance.

Component Failures

Over time, inverters may experience component failures due to wear and tear or external damage. Regular inspections for loose connections, corrosion, and general wear can help identify and resolve issues before they affect system performance. Find out how to identify and prevent component failures5.

Regular Maintenance

Routine maintenance is essential for keeping your inverter running smoothly. Regular cleaning, checking wiring, and inspecting the system for signs of wear can help prevent common errors and extend the lifespan of the inverter. This article outlines the importance of routine maintenance6 for inverters.

How Can You Ensure the Longevity of Your Deye Inverter?

Ensuring the longevity of your Deye inverter is about more than just avoiding errors—it requires proactive maintenance, proper environmental protection, and strategic upgrades. By keeping your inverter well-maintained, you can maximize its service life and efficiency.

To maximize the longevity and efficiency of your Deye inverter, it’s essential to implement regular maintenance, proper installation, and safeguard it from environmental damage.

Electrical box warning

Proper Installation and Ventilation

The installation location plays a crucial role in the longevity of your inverter. It should be installed in a cool, dry, and shaded environment to prevent overheating and reduce the risk of moisture damage. Ensure that the area is well-ventilated to allow for effective cooling, as high temperatures can degrade the inverter’s internal components over time. Avoid installing the inverter in areas with direct sunlight, dust accumulation, or high humidity, as these can negatively impact performance and lifespan. Learn more about best practices for inverter installation and ventilation7.

Regular Cleaning and Inspection

Inverters can accumulate dirt, dust, and debris over time, which can block air vents and hinder heat dissipation. Cleaning your inverter regularly ensures it operates efficiently. Pay special attention to the cooling fins and vents, as blocked airflow can lead to overheating, reducing the inverter's lifespan. Additionally, inspect the system for signs of wear and tear, including loose wiring, corrosion, or damaged components. Addressing small issues early can prevent bigger, more costly problems down the line. Understand why regular cleaning and inspection8 are crucial for inverter longevity.

Firmware Updates

Firmware updates can address bugs, improve performance, and add new features to your inverter. Ensure that you check for software updates periodically. Keeping your firmware up-to-date helps optimize the inverter’s performance and may prevent errors related to software malfunctions. Updates are often available through the inverter’s monitoring system or the manufacturer’s website, and it’s recommended to apply them as soon as they’re available. Learn how firmware updates9 can improve inverter performance.

Surge Protection

Installing surge protection devices is an important step in protecting your inverter from sudden spikes in voltage, especially during storms or power grid instability. Surge protectors will help shield your inverter from electrical surges, which can cause internal damage. This small investment can save you from potentially expensive repairs or replacements. Additionally, consider using a power conditioner to filter out any irregularities in the electrical supply that could affect the performance of your inverter. Find out how surge protection10 works to safeguard your inverter.

Monitoring System

Many Deye inverters come with an integrated monitoring system that allows you to track the system's performance in real time. Regularly monitor your system’s output and performance to catch any issues early. The monitoring system can alert you to abnormal readings, which may indicate issues such as low battery voltage, grid problems, or other errors. By keeping an eye on these data points, you can prevent minor issues from escalating into major failures. Learn more about the importance of monitoring11 your inverter’s performance.

Conclusion

Maintaining your Deye inverter through regular maintenance, proper installation, and timely troubleshooting can help ensure its longevity and efficiency.

-

This link provides detailed explanations on common causes of communication failures in solar inverters, helping you understand how to prevent them. ↩

-

Clicking here will give insights into why overvoltage and undervoltage occur, and how to prevent them from affecting your system's performance. ↩

-

This resource explains what ground faults are, how they occur, and how to prevent them to keep your inverter running smoothly. ↩

-

Clicking this link will help you understand the impact of extreme environmental conditions such as high temperatures, moisture, and dust on inverter performance. ↩

-

This article will guide you through the signs of wear and tear in inverter components, including common causes like corrosion and loose connections. ↩

-

This resource explains the importance of regular maintenance to ensure optimal inverter performance, reduce downtime, and extend the life of the system. ↩

-

This article explains the optimal environmental conditions for installing an inverter, including proper ventilation and protection from environmental factors like dust and humidity. ↩

-

Clicking this link will provide insights into the importance of regular cleaning and system inspections for maintaining inverter efficiency and lifespan. ↩

-

This resource explains how firmware updates can improve inverter performance, fix bugs, and enhance functionality, helping you keep your inverter running smoothly. ↩

-

This article will guide you on the importance of surge protection and how it prevents damage from electrical surges and power grid instability. ↩

-

Learn how regularly monitoring your inverter’s performance can help identify issues early, preventing costly repairs and ensuring optimal system efficiency. ↩